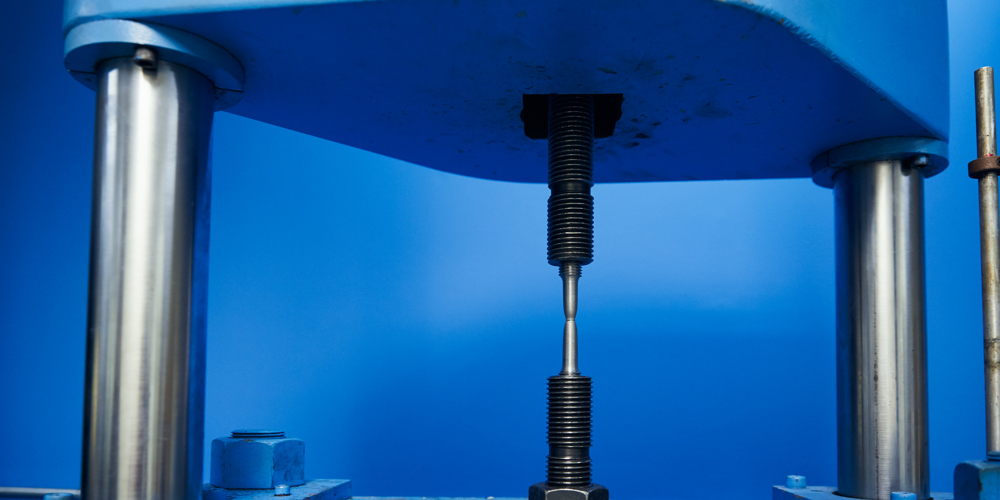

Combining advanced laboratory analysis with technical expertise, we investigate material properties, behavior, and degradation to optimize material performance and mitigate risks. Our laboratories are equipped with destructive and nondestructive testing equipment to evaluate material properties for applications in transportation, power generation, and various industries.

Our multidisciplinary team includes metallurgists, experts on ceramics, glass, and composites, and polymer and elastomer chemists. We apply optical microscopy, borescope examination, and 3D laser scanning to provide clients with a clear view of critical components and assess fatigue, corrosion, and wear as well as scanning electron microscopy (SEM) and computed tomography (CT) which reveal hidden details.

We offer expertise in materials characterization and failure analysis for investigations and use Finite Element Analysis (FEA), design optimization, and product lifecycle assessment to provide clients with the information they need to understand challenging situations.

Ensuring Product Quality and Safety

Steven Counts

Laboratory Development Director, Senior Technologist

ESi Materials Testing Capabilities

- Adhesives and Sealants

- Construction Materials

- Corrosion Evaluation

- Elemental and Phase Characterization

- Failure Analysis

- Fatigue and Fracture

- Fourier Transform Infrared Analysis (FTIR)

- GC Mass Spectrometry

- Hazardous Materials Safety

- Mechanical Testing

- Metallography

- Polymer Characterization and Testing

- Safety and Reliability Analysis

- Service Life Prediction

- Stress Analysis

- Finite Element Analysis (FEA)

- Thermal Analysis

- Explosive, Incendiary, and Gunshot Residue Analysis

- Computed Tomography (CT) Scanning

- Non-Destructive Testing