Metals and metal alloys compose the majority of products, components, and structural materials used in our everyday lives. When a failure occurs, a metallurgist is commonly engaged to understand a component’s failure mode and whether it caused an accident or was the result of it. Specialized equipment is typically used, including optical microscopy, scanning electron microscopy (SEM), and materials testing. The process can include understanding a product’s design specification and whether it comported to it and was manufactured properly.

Metallurgists often work closely with other engineering disciplines to understand how a product was used and the environment in which it was used - both of which can importantly impact an understanding of a failure. A common example would be engaging mechanical engineering expertise to perform stress analysis on a component using finite element analysis (FEA).

ESi has extensive lab and inspection facilities in all of our larger offices across the country. Our seven laboratories are equipped with state-of-the-art scanning electron microscopes (SEM's), and additional enhanced technical and testing capabilities.

In a major recall of installed pipes in a Middle East gas field, an ESi statistical analysis supported the initial premise that a large proportion of pipes failed to meet the technical specifications.

An investigation was performed to identify the root cause of "stardust" defects on a plated firearm, to determine their nature, location and provide corrective actions.

Metal fragments were found in the milled bone used for spinal fusion surgeries. ESi’s in-depth metallurgical and design analysis cleared the OEM of breach of contract and anti-competitive practice lawsuits.

A replacement wheel bearing with significant design differences from the original equipment manufacturer fails and causes permanent injury.

ESi investigated the root cause of a failed railroad wheel and determined that the reason for the failure was environmental rather than a result of human error.

Utilizing fire-damaged components as well as virgin aluminum alloy 2024-T3, ESi developed a clear correlation between electrical conductivity and mechanical properties of damaged and as-specified material.

Broken gear teeth from the clutch mechanism of a marine sterndrive unit were analyzed and determined to be a result of long-term wear leading to fatigue cracking of the gear teeth.

An ESi investigation combines metallurgical, mechanical and chemical analysis to determine the cause of a rifle accident. ESi ultimately contributes the powder analysis to the National Center for Forensic Science Smokeless Powders Database.

Localized corrosion to carbon steel boiler tubes was the result of localized boiling and scouring of protective oxides on the tube wall. Metallurgical and chemical analysis revealed no indication of stress-induced failure.

Using a combination of chemical and metallurgical principles, ESi determined that stainless steel kitchen components could be restored to their pristine state.

The customer was delighted in the confirmation of their initial response to their European customer--that the parts met the drawing requirements for roughness and surface flaws and were structurally sound for their intended, albeit very rough, use in grinding railroad rail profiles.

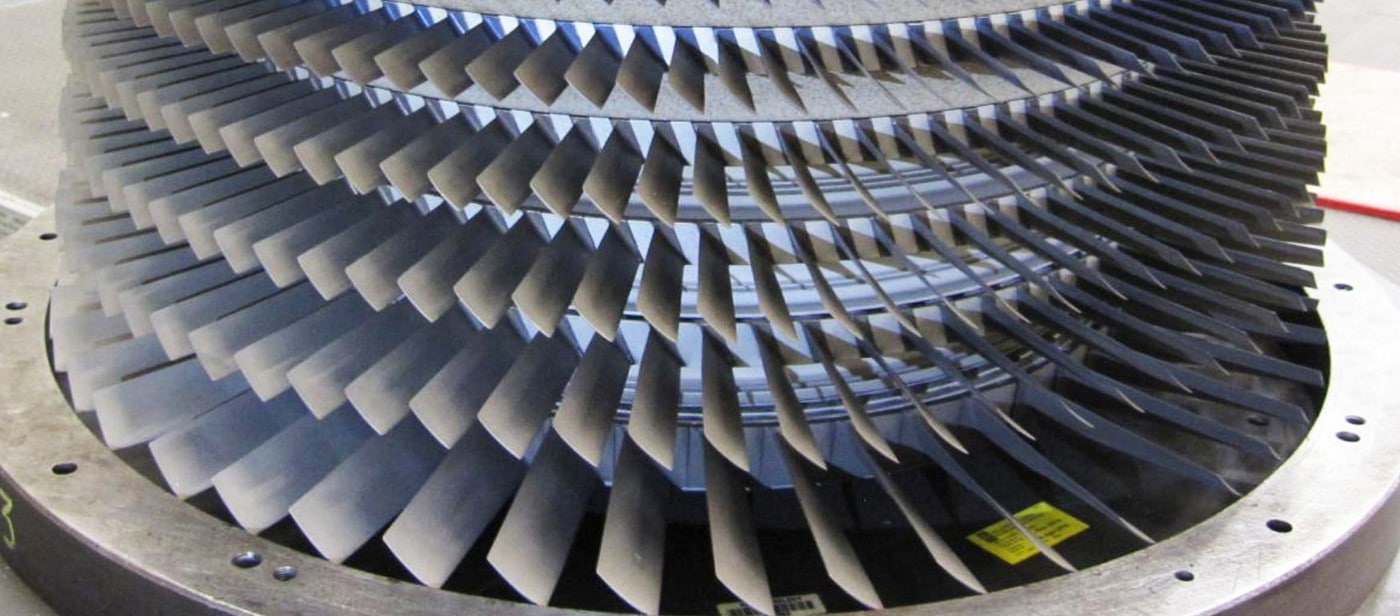

ESi’s extensive aviation experience includes deep expertise in high temperature turbine blade superalloys. We routinely diagnose blade issues such as metallic creep, fatigue cracking, and sulfidation corrosion.

Based on the results and findings of this multi-component failure analysis, the client was able to remedy the problems with the new machinery design by addressing the weld defect and successfully launch the new product line.

ESi investigated an issue involving the performance of the high temperature superalloy used in the turbine blades of a commercial aircraft engine.

A large, heavy-lift crane collapsed resulting in three fatalities and extensive damage to the stadium and construction equipment.

United Air Lines Flight 232 crashed and broke apart during the landing attempt.

ESi announces the opening of a new office in Kansas City, further expanding its engineering investigation and materials testing capabilities for clients in the Midwest.

ESi has acquired KARS’ Advanced Materials, a full-service materials testing lab and technical consulting firm in Anaheim, CA.

ESi announces the opening of a new ESi office in the greater Denver, Colorado area.

ESi's expertise spans dozens of industries and specializations organized across several practice groups, each staffed by dozens of in-house experts with the technical knowledge, hands-on expertise, and courtroom experience required to execute projects for and with our clients from start to finish.

Find an Expert Contact Us