Hail claims involving metal roofs with cosmetic damage exclusions oftentimes require a multi-disciplinary approach to determine if a roof has indeed been functionally damaged.

An ESi visualization helps investigators uncover which pilot was at fault in an investigation where there were no witnesses to the accident.

On December 22, 2021, the U.S. Consumer Product Safety Commission (CPSC) announced a recall of the analyzed bunk beds with angled ladders due to serious entrapment and strangulation hazards.

Crash data retrieved from the van’s Powertrain Control Module, when analyzed with scene scan data and evidence, refuted Plaintiff’s sworn testimony.

Contrary to the motorcyclist’s testimony, reconstruction of the crash showed that the motorcycle was traveling 20-29 mph over the posted speed limit when the crash occurred.

ESi performs a biomechanical analysis and reenactment of an altercation between two men to help resolve conflicting accounts of how one of the men was killed.

An investigation of injury mechanisms of the neck, crash test dummy utilization and subsequent injury causation analysis, results in a favorable verdict for a gentleman paralyzed after a physical altercation outside a filling station.

In a major recall of installed pipes in a Middle East gas field, an ESi statistical analysis supported the initial premise that a large proportion of pipes failed to meet the technical specifications.

An investigation was performed to identify the root cause of "stardust" defects on a plated firearm, to determine their nature, location and provide corrective actions.

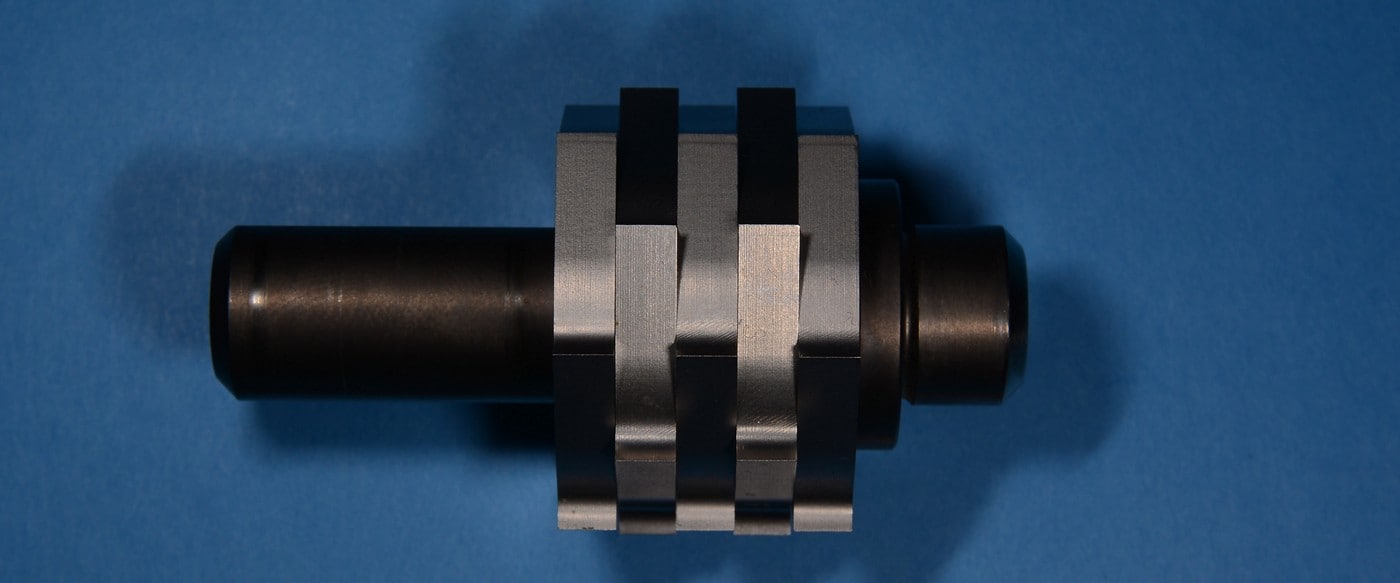

Metal fragments were found in the milled bone used for spinal fusion surgeries. ESi’s in-depth metallurgical and design analysis cleared the OEM of breach of contract and anti-competitive practice lawsuits.

Technically accurate, fast, and comprehensive support of CAT claims is essential for insurance carriers maintaining good relationships with their insured.

In a challenging and technically diverse project, ESi and our partner Oceanus provided engineering and marine survey support for crane barge operations.

Technically accurate, fast, and comprehensive structural engineering services allowed the fire origin and case investigation to move forward, and the client to retain all of their options for the subsequent dispute resolution.

On February 1, 2017, a two-year-old boy became trapped between the elevator accordion door and the elevator shaft (hoistway) door of a home in Little Rock, Arkansas.

ESi was asked to perform analysis regarding a vehicle support collapse. While a faulty jack stand was alleged, ESi investigated an alternate hypothesis in which misuse of a pump jack produced the movements and witness marks consistent with available evidence.

Investigation and analysis by ESi resulted in a favorable verdict at trial for the owner of a refrigerated warehouse following a frost heave failure of the warehouse floor.

A liquid nitrogen cryogenic freezer failed due to a defect in the electronics and specimens were lost due to operator error and a failure to properly follow procedures.

ESi performed an investigation into an explosion/flash fire that occurred during the use of a portable cookstove that caused injuries to several people.

When a top loader with its load in the fully elevated position tipped over, the operator claimed that he had sustained traumatic injuries.

ESi conducts complex multidisciplinary product analysis to determine the root cause of a failure leading to the ignition of a fire.

ESi was engaged to evaluate an alleged pitch-over bicycle accident that occurred on a city street. ESi used its experimental capabilities to test, and ultimately reject, the hypothesis posed by the opposing expert.

A replacement wheel bearing with significant design differences from the original equipment manufacturer fails and causes permanent injury.

ESi investigated the root cause of a failed railroad wheel and determined that the reason for the failure was environmental rather than a result of human error.

ESi conducted a “ladder-sequence” of multiple tests, instead of one test with a variety of variables, resulting in a systematic, repeatable method to demonstrate the BC401 bottle rocket was a viable ignition source of rooftop debris and roofing material.

ESi performs a complex standard of care investigation of an oil pipeline leak located in an urban high consequence area.

Utilizing fire-damaged components as well as virgin aluminum alloy 2024-T3, ESi developed a clear correlation between electrical conductivity and mechanical properties of damaged and as-specified material.

Broken gear teeth from the clutch mechanism of a marine sterndrive unit were analyzed and determined to be a result of long-term wear leading to fatigue cracking of the gear teeth.

An ESi investigation combines metallurgical, mechanical and chemical analysis to determine the cause of a rifle accident. ESi ultimately contributes the powder analysis to the National Center for Forensic Science Smokeless Powders Database.

ESi’s refrigeration and HVAC expertise provided a client with a focused investigation and testing program that ended in a successful defense against a product defect claim.

Localized corrosion to carbon steel boiler tubes was the result of localized boiling and scouring of protective oxides on the tube wall. Metallurgical and chemical analysis revealed no indication of stress-induced failure.

Using a combination of chemical and metallurgical principles, ESi determined that stainless steel kitchen components could be restored to their pristine state.

An ESi report to the NTSB finds that the airplane accident was due to failure to activate the ice protection system on final approach for landing.

The customer was delighted in the confirmation of their initial response to their European customer--that the parts met the drawing requirements for roughness and surface flaws and were structurally sound for their intended, albeit very rough, use in grinding railroad rail profiles.

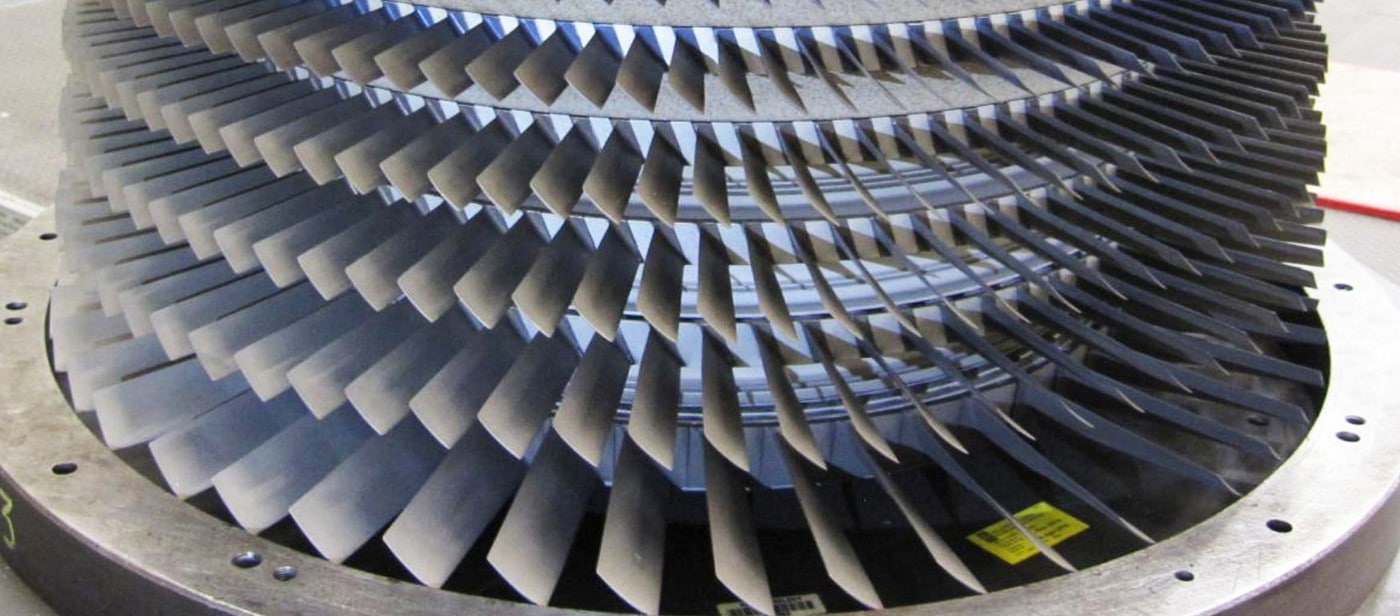

ESi’s extensive aviation experience includes deep expertise in high temperature turbine blade superalloys. We routinely diagnose blade issues such as metallic creep, fatigue cracking, and sulfidation corrosion.

The results of ESi’s investigation were used to recommend and substantiate to the USAF Technical Airworthiness Authority (TAA) a return to pressurized flight without altitude restrictions.

Based on the results and findings of this multi-component failure analysis, the client was able to remedy the problems with the new machinery design by addressing the weld defect and successfully launch the new product line.

Analysis of the ECM data confirmed the driver was operating his tractor-trailer in a reasonably safe manner and, when faced with unexpected black ice, responded consistent with the methods described in the Commercial Driver Handbook.

ESi investigated an issue involving the performance of the high temperature superalloy used in the turbine blades of a commercial aircraft engine.

A train service employee fell from a tank car while attempting to dismount the car. Repairs were made to the car prior to position of the safety appliances (sill step) being measured.

ESi was able to review and completely refute the validity of plaintiff and co-defendant testing and claims that our client’s product was defective.

ESi has been performing field and physical testing of composite railroad ties to refine industry specifications on mechanical and thermal performance.

ESi conducted a site inspection at a grocery store’s bottle return area to determine if the incident in question happened in the manner described.

An ESi investigation proving manufacturer defect prior to transport damage results in a reduced claim settlement for the client.

Two landfill gas process equipment failures at an electric powerplant cause significant unplanned downtimes and substantial repair procedures.

An ESi investigation results in a quick settlement following testing and an engineering analysis of the biomechanics and human factors surrounding a slip and fall incident in a ballroom during a wedding reception.

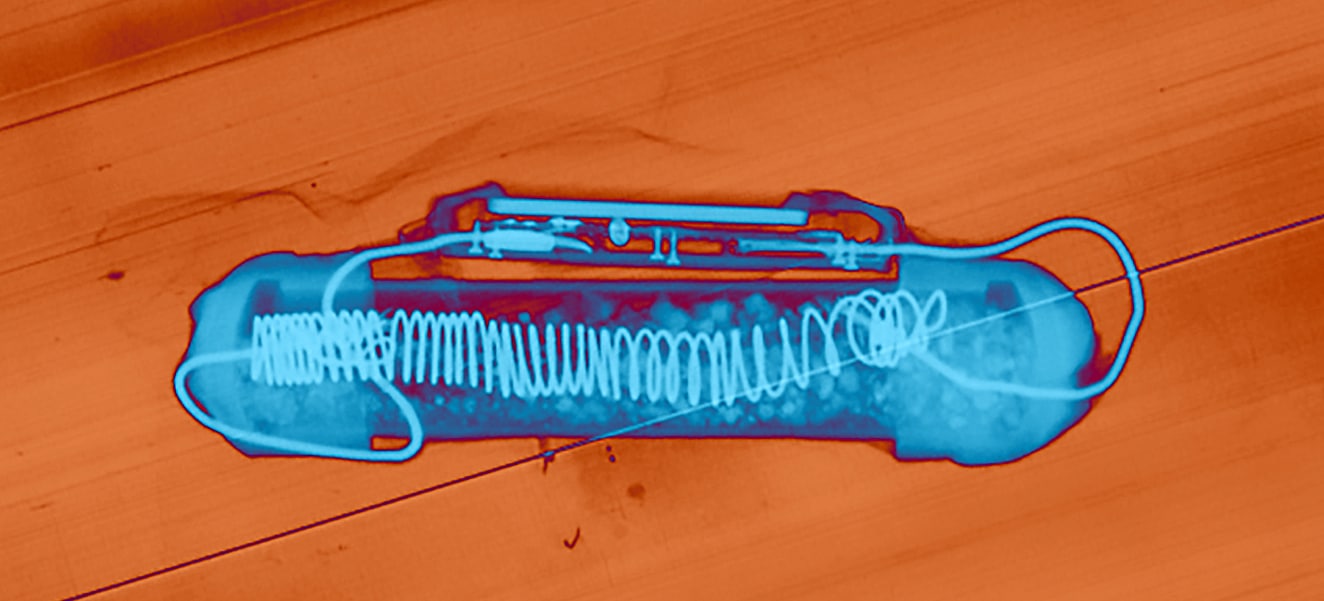

ESi reviews FBI case files and opines on the nature of 16 pipe bombs sent to a past US president, senators and celebrities.

A plant that produced iron powder for use in manufacturing metal parts had a series of three flash fires and deflagrations within a 6-month period, resulting in a total of five fatalities.

Petroleum refineries frequently need to clean storage tanks to check for corrosion, or to allow the tank to be used for a different purpose.

The company was contracted to produce a chemical, and developed a procedure for the reaction that included treating the waste water from the reaction. The waste water contained a reactive chemical that was a hazardous material.

A homeowner was treating her swimming pool with a chlorinated chemical oxidizer used to control bacteria and algae (analogous to chlorine bleach.)

The plant decided to inject these chemicals into the water system rather than dispose of them as hazardous waste.

ESi analyzed the release of natural gas from a transmission pipeline that ruptured

An ESi investigation determines the cause of a delivery truck's mechanical explosion that shot a compressed natural gas container rocketing through the air.

Our reconstruction of the accident showed that the train was not capable of stopping prior to reaching the off-limits location where the pedestrian was standing, based on the available time and distance.

Two vehicles collided at an intersection, causing one vehicle to flip onto its side. The front passenger was not wearing a seatbelt and sustained serious spinal cord injuries. ESi used HVE software to create simulations of the crash sequence, and imported the vehicle motion output into MADYMO to model both “belted” and “unbelted” occupant responses inside the vehicle.

ESi was retained by the subrogation council for the fire origin and cause analysis which also necessitated a structural engineering effort to shore the building and supervise the removal of the damaged roof.

ESi was retained to investigate the failure of a PVC pipe. The pipe showed indications of rapid crack propagation that would be consistent with a high-pressure event. In order to understand the effect of the pre-existing crack on the remaining strength of the pipe, a fracture mechanics analysis was performed.

A large cross-linked polyethylene (XLPE or PEX) storage tank for 93% sulphuric acid failed after approximately seven months of service. The release of acid occurred through circumferential cracks that developed on the bottom panel of the tank near the corner radius with the sidewall.

ESi was retained to conduct a detailed review the construction drawings and specifications, review the product literature, conduct a constructability review to identify and resolve potential issues prior to installation.

A minivan was crossing a set of multiple railroad tracks after a train had backed across the crossing on the near track and was subsequently struck by a through train traveling in the opposite direction. ESi was asked to reconstruct the locations and movements of the vehicles leading up to the crash and determine the influence of the backing train on the crash.

A small aircraft departed for a practice flight in instrument flying conditions. Shortly after takeoff, upon entering the clouds, the aircraft deviated from its clearance, beginning a series of turns, climbs and descents. Ultimately, the aircraft entered a descending right turn and impacted a home.

ESi initiated a comprehensive investigation, examining the material, its processing, the environment within the vessel and the stresses in the material during service.

In a major product liability case that went to trial, Dr. Butler reconstructed a complex tractor semi-trailer accident. The tractor semi-trailer rolled over while traveling down a mountain road.

ESi was retained by the manufacturer of personal fall protection equipment to perform a safety analysis and documented risk assessment of a newly designed detachable cable sleeve. This product provides fall protection for workers climbing fixed ladders in multiple industrial applications.

Utilizing the worker’s described scenario as the working hypothesis, data were collected to support or rule out this sequence. ESi’s investigation included a site inspection to evaluate the scene and measure the distances between the platform, ground, and rail.

Eyewitness testimony was inconsistent regarding the initial location. ESi needed to evaluate the physical evidence of the geometry of the staircase, the railings, and her final location to determine what fall scenarios could be consistent with the laws of physics.

ESi was retained to evaluate the pre-impact motion and positions of a tractor semitrailer and a pickup. The intent of the time-distance-speed analysis was to provide an estimate of the coordinate pre-impact motion of the vehicles based on reasonable assumptions for evaluation of the circumstances.

A hopper car loaded with ammonium nitrate was an innocent bystander at West Texas fertilizer distribution facility explosion.

This project involved a passenger car stopped in the roadway, while a garbage truck allegedly backed into the front of the vehicle. The driver claimed she observed the garbage truck backing up for approximately 30 seconds and that the truck was traveling at approximately 30 mph.

In 1994, a Boeing 737 was scheduled to fly 127 passengers from Chicago O'Hare International Airport to Pittsburgh International Airport. The aircraft crashed while on approach to Pittsburgh International Airport, killing all aboard.

ESi was retained to investigate an aviation crash involving airplane impacting power lines and terrain and pilot and passenger fatally injured.

ESi was retained to perform a cause and origin evaluation on a fire in a large power plant.

ESi was retained to perform a study on the degradation of HDPE piping resulting from exposure to the disinfectants used in potable water.

ESi was retained to investigate an accident of a Porsche Carrera GT.

ESi was retained to investigate damage to a rail tank car and subsequent release of hazardous materials resulting from a derailment.

A freight train derailed while passing through the Howard Street tunnel in Baltimore, Maryland.

ESi was retained to determine the cause of failure of a woven polypropylene (PP) belt.

ESi was called in to assess the structural, mechanical, and electrical elements of the Super Dome after Hurricane Katrina.

A large, heavy-lift crane collapsed resulting in three fatalities and extensive damage to the stadium and construction equipment.

United Air Lines Flight 232 crashed and broke apart during the landing attempt.

Biomechanical accident reconstruction analysis methodologies were used to address injury modes associated with human operator involvement with a commercial hand fed tree chipper winch line.

A female pedestrian wearing black clothing was injured when an automatic sliding door closed on her while she was standing at the right door threshold. An accident reconstruction was performed to document the injury mechanism.

A mechanic in a shop that builds MOW specialty vehicles was lifting an articulating crane to mount it on a truck bed when the sling failed. The mechanic was fatally injured when the load fell to the ground and toppled on top of him.

ESi's expertise spans dozens of industries and specializations organized across several practice groups, each staffed by dozens of in-house experts with the technical knowledge, hands-on expertise, and courtroom experience required to execute projects for and with our clients from start to finish.

Find an Expert Contact Us